What Are Pneumatic Tires? Why are They Preferred for Outdoor Operations?

Every industry is highly dependent on heavy-load vehicles for transportation purposes. These heavy-load vehicles have to cover every kind of terrain, whether it’s even or uneven. It is very important to choose the right wheels that can help these vehicles maintain their balance and work efficiently. To sort this purpose, pneumatic tires come into play. Pneumatic tires are rubber tires that are used in heavy-load vehicles like buses, trucks, and tractors.

What are Pneumatic Tires?

What does the term pneumatic tires mean? The following sections will give you a complete understanding of pneumatic tires, their definition, advantages, and more.

Pneumatic tires definition: The rubber tires that are usually used in heavy-load vehicles. These tires are very popular as they eradicate the effect of bumps and jolts felt by the driver or the passengers. Known for their superior rubber treads, pneumatic tires have tremendous shock absorption quality.

These tires are hollow and inflated with pressurized air. The different types of pneumatic tires are:

- Solid Pneumatics: Solid pneumatics are entirely made up of rubber and are more expensive than air pneumatic tires.

- Air Pneumatics: Air Pneumatic tires are filled with air, which offers them the flexibility to offer a smooth ride.

Advantages of Pneumatic Tires

Pneumatic wheels offer many benefits to the heavy load vehicles:

- Shock Absorption: While driving on uneven terrain, pneumatic tires often absorb shocks. This reduces the impact of bumps and jolts felt by the driver and passengers.

- Better Traction: Heavy-load vehicles equipped with pneumatic tires can easily operate off-road. The inflated air inside the wheels allows them to improve the traction so that the vehicle can be stabilized and controlled.

- Versatility: Pneumatic wheels are versatile, meaning that they can easily adapt to increased pressure due to heavy load. This is a very important characteristic feature of pneumatic wheels that is beneficial for heavy-load vehicles in different types of terrains.

- Fuel Efficient: These wheels are fuel efficient. The cushioning effect inside pneumatic cylinders reduces rolling resistance, which in turn increases the fuel efficiency of the vehicle.

- Durability: The Pneumatic tires are designed to evenly distribute the load across each wheel surface. This allows them to be durable and prevent wear and tear.

- Safety: Pneumatic Tires contribute to the safety of a vehicle, the driver and passengers by enhancing control and stability during uneven terrains.

- Adaptability: Pneumatic tires are highly adaptable. They can perform well in every type of terrain, whether even or uneven.

- Overheating Prevention: Pneumatic wheels are designed to prevent overheating of the vehicle while in prolonged use. This ensures the safety of the passengers inside.

- Comfort: The shock-absorbing quality of pneumatic tires increases the comfort level of the driver and passengers. This way, the jolts and bumps do not adversely affect them.

- Vibration Reduction: Pneumatic Tires help reduce vibrations that are caused due to the movement of the vehicle.

Tire Material

Pneumatic wheels are made up of rubber and other materials. These materials include:

- Tire Carcass: The Tire Carcass consists of Cords and Beads. The cords are made up of rayon or nylon, whereas beads are made up of high-strength steel wires.

- Tire Inner Liner: The Inner Liner of Pneumatic wheels is made up of synthetic rubber compound. The inner liner ensures the escape of compressed air.

- Tire Body Plies: The Tire Body Ply layer is made up of nylon or rayon. These layers provide flexibility to the tire.

- Tread Compound: The Tread compound is the outlayer of the wheel that comes in contact with the road surface. It is made up of a rubber compound consisting of carbon black and silica, which enhance the overall performance of the wheel.

- Sidewall Compound: The Sidewall Compound is the part between tread and beads. This layer is made up of polyester and protects against abrasion.

- Belt Package: Belts are layers made up of steel and are located between treads and tire body plies. The belts help in improving the stability and control of the vehicle.

- Cushion Gum: This is the layer that bonds the tire body and plies with the tread. It helps in joining and improving the overall integrity of the wheel.

Applications of Pneumatic Tires

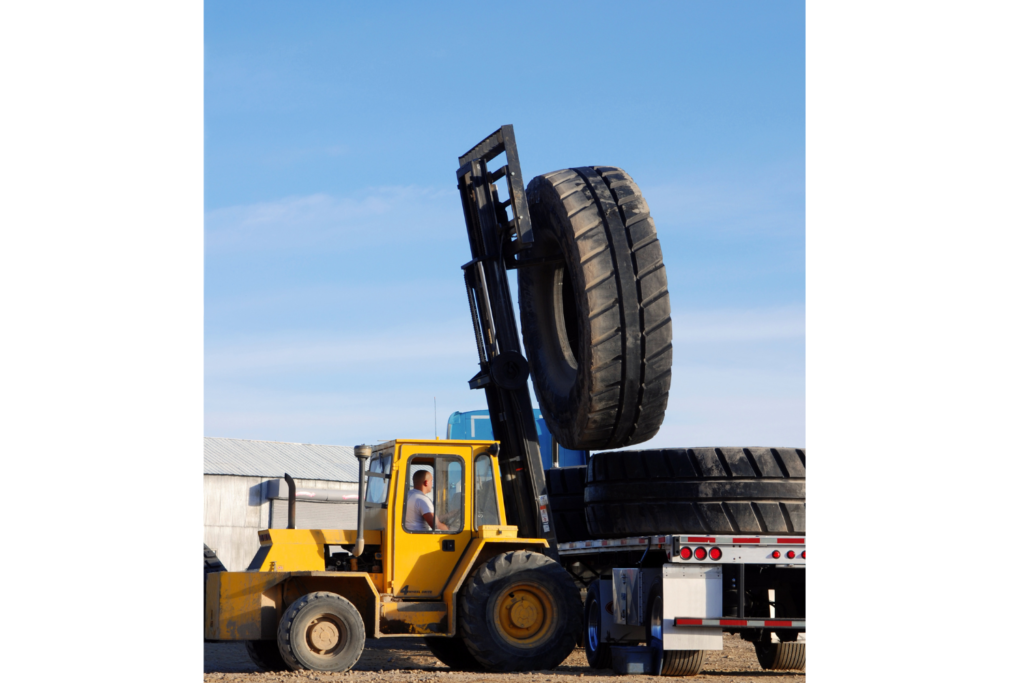

A Pneumatic tire can be used for construction vehicles like Tractors and transportation of heavy loads across uneven terrains. The most common application of these tires is on forklifts, where these tires serve as good-weight carriers.

Other applications of Pneumatic wheels include:

- Electric Forklifts

- Heavy-duty Forklifts

- Electric Pallet Stackers

- Electric Pallet Jacks

- Wheelbarrows

- Hand Trucks

- Tractors

The primary benefit of these tires is the potential to cope up with uneven surfaces. Pneumatic tires are designed to absorb the unevenness of the surfaces.

Conclusion

Pneumatic tires are highly preferred by heavy-load vehicles because of their ability to cross uneven surfaces and provide a seamless experience for the operator and the passenger. These wheels are safe and durable, and their shock absorption quality makes them a perfect choice for long routes.

Frequently Asked Questions about Pneumatic Tires

1. How to take care of pneumatic tires?

The care and maintenance of pneumatic tires can be done through proper inflation at the recommended level, avoiding unnecessary spins, checking for wear and tear, and always using the right tire as per the instruction guidelines.

2. What are the disadvantages of pneumatic tires?

The disadvantages of pneumatic tires are associated expenses, the possibility of punctures in air-filled tires, the challenge of getting the right tire pressure, susceptibility to temperature, and less maneuverability.

3. What is the purpose of the tread pattern on pneumatic tires?

The tread pattern serves multiple purposes, such as enhancing the fraction on different surfaces, providing improved grip on wet roads, and assisting in water dispersion, thus avoiding hydroplaning. It also contributes to even tire wear, which extends a tire’s lifespan.

4. Why is nitrogen used in pneumatic tires instead of regular air?

The increased usage of nitrogen compared to regular air in pneumatic tires owes to higher stability. The gas reduces pressure loss over time, minimizes the corrosion and oxidation within the tire, and aids in maintaining consistent tire pressure. It also contributes to improved fuel efficiency and longer tire life.

5. What is the effect of tire pressure on the performance of pneumatic tires?

The correct tire pressure is essential for pneumatic tires to avoid several damages. The situation of underinflation can lead to reduced fuel efficiency, a higher risk of tire damage, and increased resistance to rolling. Overinflation, on the other hand, has consequences of the harsh ride and uneven wear of tires.